(This is a contributed guest column. To be considered as an MJBizDaily guest columnist, please submit your request here.)

In August, California’s Department of Cannabis Control issued five marijuana product recalls that cited the presence of aspergillus, bringing the total number of such recalls to 21 for 2024.

This sharp rise in mold-related recalls – particularly for aspergillus – has cannabis cultivators across the state on high alert.

While most strains of this common mold are harmless, certain species can cause severe respiratory problems in people with weakened immune systems, asthma or underlying lung conditions.

With the health of consumers and the profitability of cultivators at stake, a “decontamination step” or “kill step” in the cultivation process can act as a proactive safeguard.

Aspergillus and cannabis

Aspergillus thrives in warm, humid environments and can be found in soil, decaying vegetation and even the air.

Its tiny spores can travel long distances, making them difficult to contain in indoor or outdoor grow operations.

While most people are not affected by aspergillus exposure, certain species can cause infections, ranging from mild allergies to invasive aspergillosis, a potentially fatal condition.

Given that medical cannabis is often used by immunocompromised patients, the stakes are even higher when it comes to ensuring mold-free products.

Reacting to mold

When a marijuana product fails a state-mandated lab test because of high levels of mold, the options for cultivators are costly.

Failed products are typically remediated or turned into extract, both of which result in reduced profit margins.

Specifically, remediated flower is flagged in Florida-based Metrc’s cannabis track-and-trace systems and labeled with an “R” in the supply chain, which negatively affects its market appeal and drives price erosion.

This reactive approach is not sustainable for marijuana cultivators trying to maintain a competitive edge and profitability.

Additionally, when the federal government decides to regulate cannabis, officials likely will approach it like any other agricultural commodity or medical product and require cultivators to treat flower for mold and pathogens before testing.

The milk industry, for example, pasteurizes all milk before sale out of an abundance of caution.

Cannabis decontamination

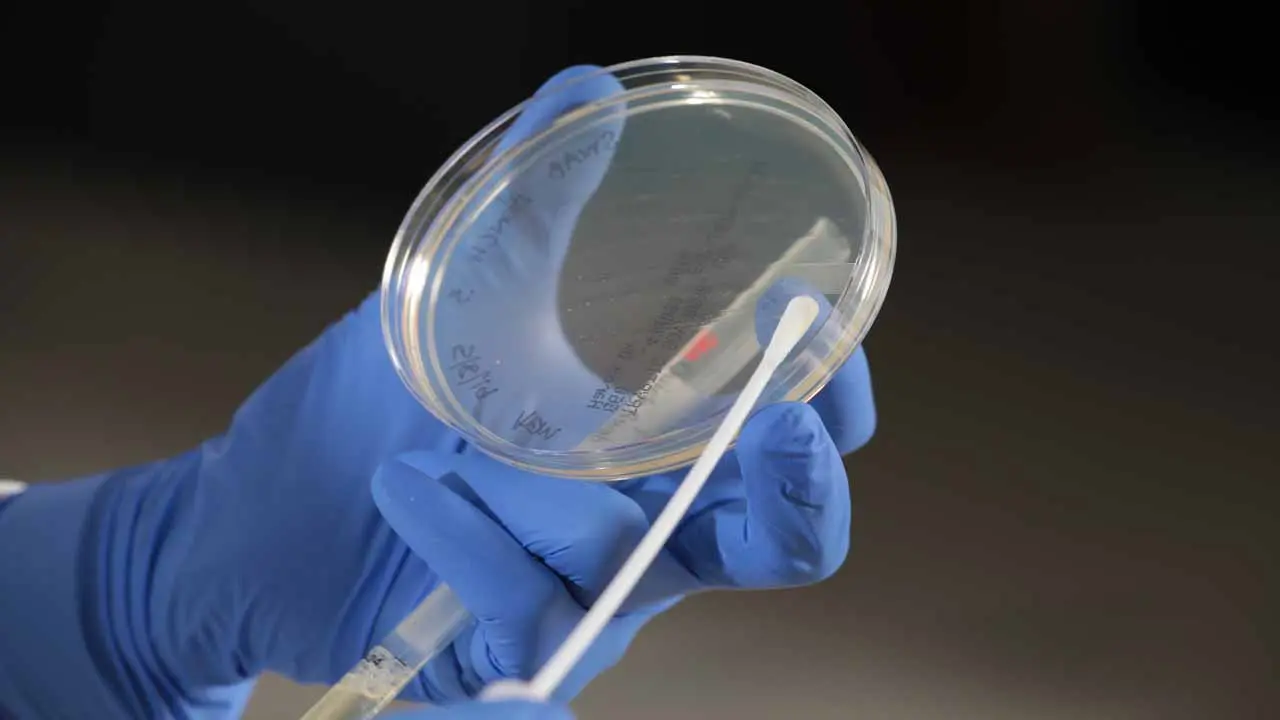

A microbial control step or decontamination step can significantly reduce the presence of mold before marijuana products are submitted for lab testing.

A decontamination step aims to reduce the microbial levels present in the flower, typically through a sanitization or sterilization process.

By integrating this precautionary measure into their standard operating procedures, cultivators can avoid the financial and reputational damage associated with failed lab tests and product recalls.

Despite the benefits, some operators in the industry have been hesitant to adopt a decontamination step, afraid that it signals a mold issue within the grow facility.

However, the reality of cultivating agricultural crops is that mold and other pathogens are ever-present threats that spread through air, water and human contact, regardless of how clean a facility might be.

Fortunately, solutions exist that do not compromise the quality of the marijuana flower.

Decontamination solutions

Several solutions exist to eradicate aspergillus and other molds and pathogens from cannabis:

- Radio frequency treatment is a method approved by the U.S. Food and Drug Administration and Department of Agriculture to kill pathogens in the food industry; it generates heat evenly throughout cannabis flower and has negligible impact on terpenes, trichomes or appearance.

- X-ray radiation emits photons that penetrate the flower and deactivate harmful pathogens’ DNA.

- Ozone gas significantly reduces microbial levels on plant material, including cannabis.

2024 MJBiz Factbook – now available!

Exclusive industry data and analysis to help you make informed business decisions and avoid costly missteps. All the facts, none of the hype.

Featured inside:

- Financial forecasts + capital investment trends

- 200+ pages and 49 charts highlighting key data figures and sales trends

- State-by-state guide to regulations, taxes & market opportunities

- Monthly and quarterly updates, with new data & insights

- And more!

Protecting your brand

For marijuana cultivators, a product recall can be catastrophic – not only in terms of lost revenue but also in terms of damaged public perception.

If a consumer purchases a recalled product or one that contains mold, they will likely not give the brand a second chance.

With many of the nation’s largest regulated marijuana markets increasingly saturated, consumers can easily switch to another brand.

Product recalls have the power not only to damage a brand’s reputation with consumers but also the entire distribution system.

In an industry as competitive as marijuana, cultivators might not get a second chance.

Arthur de Cordova is the co-founder and CEO of Ziel, a San Francisco-based provider of microbial control solutions for the agriculture and cannabis industries. He can be reached at arthur.decordova@ziel.com.

Medical Disclaimer:

The information provided in these blog posts is intended for general informational and educational purposes only. It is not a substitute for professional medical advice, diagnosis, or treatment. Always seek the advice of your physician or other qualified healthcare provider with any questions you may have regarding a medical condition. The use of any information provided in these blog posts is solely at your own risk. The authors and the website do not recommend or endorse any specific products, treatments, or procedures mentioned. Reliance on any information in these blog posts is solely at your own discretion.